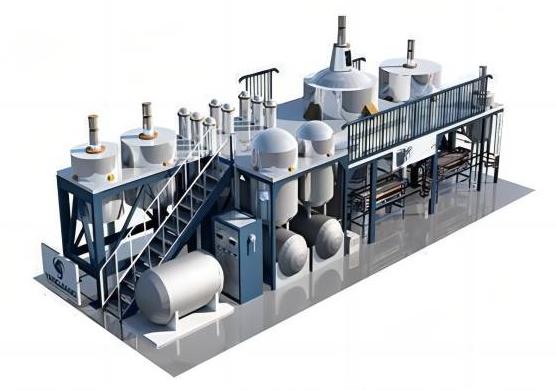

Traditional diesel desulfurization requires large refinery setups, but what about remote locations, marine vessels, or small-scale industries? Portable desulfurization units offer a flexible solution, enabling on-site sulfur removal without massive infrastructure.

https://www.oilrecyclingplant.....com/yj-snc-diesel-de

purepath purepath

Base oil solvent extraction is a critical process in lube oil refining, where undesirable components like aromatics, sulfur, and nitrogen compounds are removed to improve viscosity index, oxidation stability, and overall performance. While the fundamentals of solvent extraction are well-established, optimizing efficiency remains a challenge. Advanced process control (APC) strategies can significantly enhance yield, reduce solvent consumption, and minimize energy costs.

https://www.purepathtech.com/b....ase-oil-solvent-extr

The petrochemical industry is continuously evolving to meet growing demand for cleaner fuels and high-value chemical products. One critical process in refining and petrochemical operations is hydrotreating, which removes impurities like sulfur, nitrogen, and metals from hydrocarbon feedstocks. Integrating hydrotreating units within petrochemical complexes offers significant advantages, including improved efficiency, cost savings, and reduced environmental impact.

https://www.purepathtech.com/hydrotreating-plant

The raffinate from the waste oil solvent extraction process can then be further refined to enhance its properties and ensure its suitability for lubricant formulation.

https://www.purepathtech.com/o....il-solvent-extractio

One of the primary goals of a solvent extraction plant is to improve the viscosity index (VI) of base oils. Viscosity index is a measure of how much the viscosity of an oil changes with temperature.

https://www.purepathtech.com/b....ase-oil-solvent-extr